The Unified ATC system is a set of control features — PLC program, CNC macros, and front-end interface features — for operating many typical vertical machining centers with either umbrella-type (sliding carousel) or swing-arm type (side mount carousel) automatic tool changers.

PLC packages are available for controls based on the Oak board; on the GPIO4D board with and without the OpticDirect drive interface; on the All-in-one DC unit; and on the LegacyAdd interface to older RTK3 SD-drive systems.

Umbrella-type tool changers are also often called "non-random" tool changers, because any given tool is always stored in the same carousel location ("bin").

Swing-arm type tool changers are also often called "random access" tool changers, because the previous tool is put away in the carousel bin that the new tool just came out of. As a result, the carousel location of any given tool changes every time it is used.

This manual primarily applies to swing-arm type tool changers.

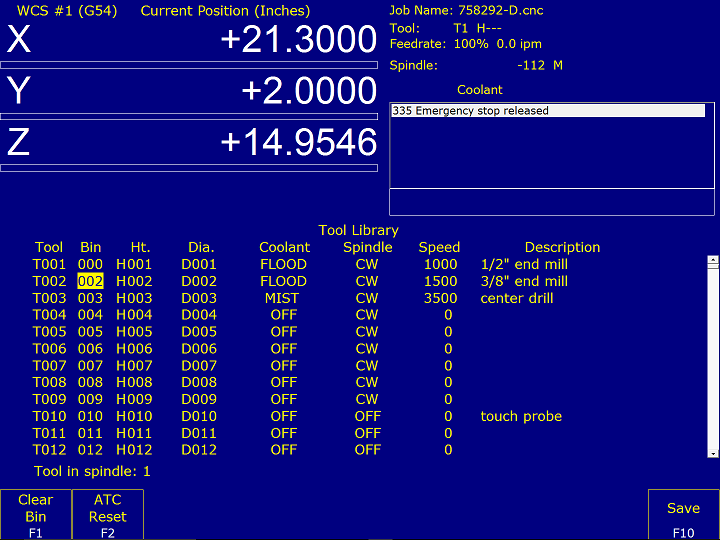

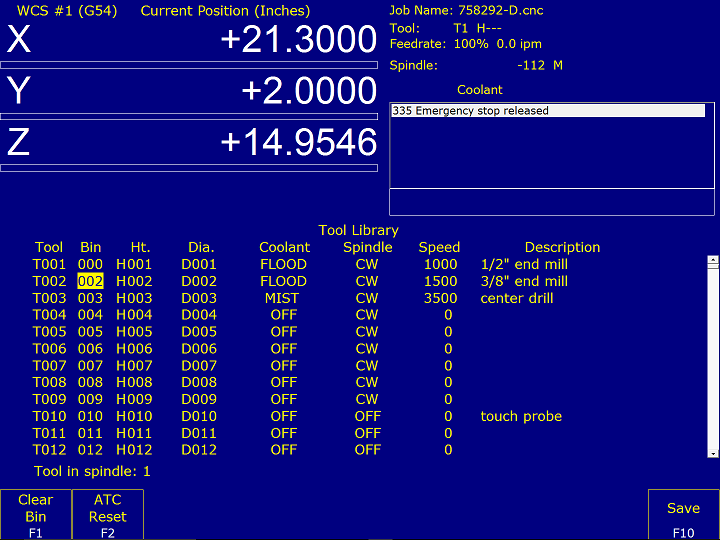

Tool descriptions and locations are stored in the Tool Library.

To get to the Tool Library, press F1/Setup → F2/Tool → F2/Tool Lib.

The Centroid tool library has space in its list for up to 200 tools. A typical machine might have 16 or 24 positions, or "bins", in the tool carousel.

You can use the Bin column in the Tool Library to specify which carousel bin a given tool is stored in.

If you are just starting out with an ATC machine, you will find it easiest to use only the first 16 or 24 tool numbers, so that your initial bin positions can match your tool numbers. When you become more comfortable with the Tool Library and the ATC, then you can expand your tool list and use all 200 tool numbers if you wish.

Use the F1/Clear Bin key on the Tool Library screen to clear the bin number for the selected tool, indicating that that tool is not in the carousel. If a tool is not in the machine, its Bin number will be shown as "-1". If a tool is currently in the spindle, its Bin number will be shown as "000".

You cannot change or clear the bin of the tool currently in the spindle.

When you run a CNC program cycle, the program will generally call out the tools it needs, when it needs them, and the control system will change tools automatically.

During setup and manual operations, you may need to have the machine change tools (put the current tool away in the carousel, and get out a different one) outside of any CNC program.

You can do that in one of two ways:

To remove a tool:

To load a tool:

* On some machines with CAT-standard tooling, it is important to orient the tool holder so the deeper notch is towards the tool-pot key when the tool is put away. If you have such a machine, you should mark the spindle drive key which aligns to the deeper notch (the key which translates to the pot key when the spindle is oriented) so that you can always insert tool holders in the proper orientation.

When you load and unload tools by hand as described above, the control system and PLC do not register any change. If the control previously expected that Tool 7 was in the spindle, then on the next tool change, it will record that tool 7 was put away in the carousel.

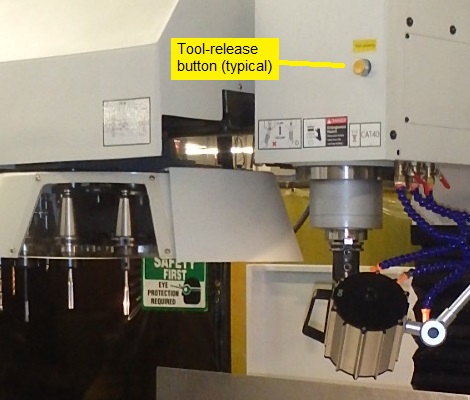

The simplest way to load the desired tools into the carousel is through the spindle, using the F7/ATC key on the Setup menu, and the manual tool-release button on the machine head.

For example, suppose your next job requires tools #1, #2 and #7, and you have those tools on the tool cart in front of the machine.

Generally, no special codes are required in your CNC programs in order to use the automatic tool changer. The same M6 code works for both manual and automatic tool changing.

To change to a new tool, program T__ M6. If the machine and control are properly set up to use the tool changer, then the control will look up the location (bin number) for the requested tool, and the PLC system will pick up the new tool from its assigned bin and put away the previous tool.

Optionally, you can program M17 at the end of the last cut with each tool, as soon as the cutter is clear of the material, prior to moving Z to home and changing tools. M17 will turn off the spindle and coolant, and begin the spindle orientation sequence. This allows the spindle to orient while Z is moving to home, saving a few seconds in the tool change.

Optionally, after an M6 tool change, you can also program M107 T__ to pre-stage the next tool that will be needed. M107 will cause the carousel to rotate around to the specified tool, even as the machine is cutting with the tool that was just loaded. This saves time on the next tool change.

If an error occurs which causes the automatic tool change sequence to be interrupted, you will need to take a few steps to ensure that the control is ready to run again, before you can restart the job.

First, you will need to return the tool changer components to their idle, "ready" positions. For a swing-arm type ATC, the ready positions are:

If the tool pot is not swung out of the way, either use the Aux1 key

in Maintenance Mode (see below) or press

the mechanical override button on the pot-down solenoid valve, if

your machine is so equipped.

If the tool pot is not swung out of the way, either use the Aux1 key

in Maintenance Mode (see below) or press

the mechanical override button on the pot-down solenoid valve, if

your machine is so equipped.

If the transfer arm is not parked back in its idle position, use the Aux6 key in Maintenance Mode to drive it forward until it stops in the parked position (but see below if the arm is gripping a tool in the spindle).

If the carousel is not centered on a tool position, then use the

Aux8 (Tool Index -) or Aux9 (Tool Index +) keys to move it into an

aligned position. In this case, take particular care to verify that

the carousel position reported by the control (e.g. in the "Possible ATC Fault"

prompt below, or when you press Alt-K) is correct.

If the tool change process was interrupted after the first arm move — from its parked position to where it is gripping the old tool in the spindle and the new tool in the carousel pot — then you will want to reverse the arm back to its parked position, rather than driving it forward through the tool exchange.

If your machine is equipped with a reversing starter for the arm motor, then you can use the Aux5 key in Maintenance Mode to drive the arm in reverse, back to the parked position.

If your machine is not equipped with a reversing starter for the arm motor, then you can use a hex wrench to turn it back manually. The arm motor should have a brake release lever which you can use to free the motor; and it should have a hex head on the back shaft, which you can use to turn it.

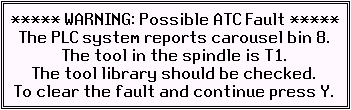

The next time you begin an automatic program cycle after a tool-change

failure — running a program,

homing after powerup, or using the F3/MDI prompt — the control will

display a message noting that the last tool change failed, and prompting you

to confirm the state of the tool changer.

The control will assume that no tool exchange has happened. Therefore, if the error which interrupted the tool change happened before the tools were swapped, you can generally just acknowledge the prompt by pressing the 'Y' key.

If the tools did get swapped, then you will need to perform an extra tool change, to get back to a state that matches the tool library. To do this:

If the tool library has been corrupted and it seems that things are hopelessly confused, you can use the ATC Init function on the Configuration menu to reset the tool library and the ATC state.

After an ATC Init, the control will expect that the carousel is at position #1; that Tool #1 is in the spindle; and that all remaining tools (Tool #2 through however many positions are available in the carousel) are in like-numbered positions.

If you in fact have real tools occupying the carousel positions, then these bin numbers are probably not correct. Use the Tool Library to enter the correct bin numbers for each tool in the carousel; or fully unload and reload the carousel with matching bin numbers.

In normal operation, the Auxiliary keys on the jog panel have the following functions:

|

No function |  |

No function |  |

No function |

|

No function |  |

No function |  |

No function |

|

Work Light Off/On |  |

Index Carousel Minus |  |

Index Carousel Plus |

| (Aux10) | No function | (Aux11) | No function | (Aux12) | Maintenance Mode On/Off |

| (Aux13) | No function | (Aux14) | No Function |

Aux keys with no default function shown above are available for

custom PLC-controlled features, or for features assigned through

Machine Parameters 188-199. See Chapter 14 of the M-Series Operator's Manual.

M Function Summary

The following M functions are part of the ATC system:

| M6 | Change Tools |

| M13* | Cycle Arm Forward to Next Stop |

| M14* | Swing Pot Down |

| M15* | Swing Pot Up |

| M17 | Prepare for Tool Change |

| M18 | Set Current Carousel Position to be Position 1 |

| M19 | Orient Spindle |

| M50 | Index Carousel Forward One Position |

| M51 | Index Carousel Reverse One Position |

| M107 T__ | Pre-stage (rotate carousel to) Designated Tool |

* These functions are used in error recovery and maintenance, and are only available when Maintenance Mode is on.

See Chapter 13 of the Centroid M-Series Operator's Manual for descriptions of standard M functions.

The PLC program includes a "Maintenance Mode", which allows you to manipulate the tool changer components directly. This is primarily used in error recovery, but it can also be used to test or troubleshoot ATC components in isolation.

To switch Maintenance Mode on or off, press and hold the Aux12 key for one second. Aux12 is the blank gray key in the right-most column, immediately below the Aux9 or "Tool Index +" key. The LED in the Aux12 key will light up to indicate that Maintenance Mode is active.

You must cancel Maintenance Mode before you can again run normal program cycles.

In Maintenance Mode, the jog panel Aux keys have the following special functions:

|

Pot up |  |

Orient spindle / cancel orient |  |

Unclamp/clamp tool |

|

Pot down |  |

Changer arm reverse (if available) |  |

Changer arm forward |

|

No function |  |

Index Carousel Minus |  |

Index Carousel Plus |

| (Aux10) | No function | (Aux11) | No function | (Aux12) | Maintenance Mode On/Off |

| (Aux13) | No function | (Aux14) | No Function |

Also in Maintenance Mode, the following special M functions are available at the F3/MDI prompt:

| M13 | Cycle arm forward to next stop |

| M14 | Swing pot down |

| M15 | Swing pot up |

| M16 | Clamp tool |

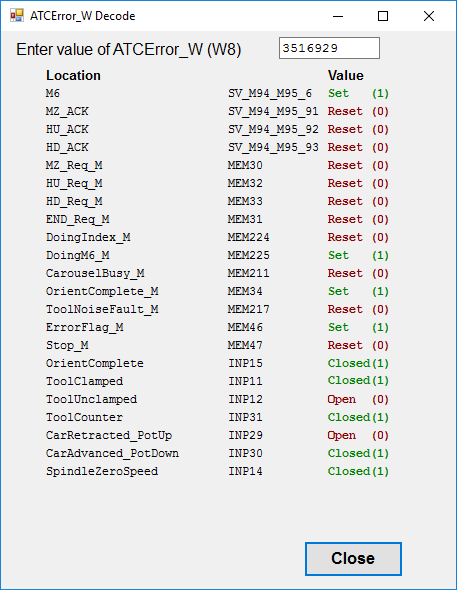

If a tool change fails for any reason, the PLC will store the state of

numerous inputs and flags in word variable W8. Use the Alt-I PLC Diagnostic

display to view the value in W8.

A separate program, named AWDecode.exe, is available to interpret and display the content of W8. You can launch AWDecode.exe from the Windows start menu. Enter the value from variable W8 in the box at the top of the AWDecode window. AWDecode will then show the state of the various input and flag bits which the PLC program has stored.

This information, combined with the actual error message which was displayed in the control's status window when the failure occurred, will often show exactly what went wrong.

Download AWDecode

PLC Diagnostic Display

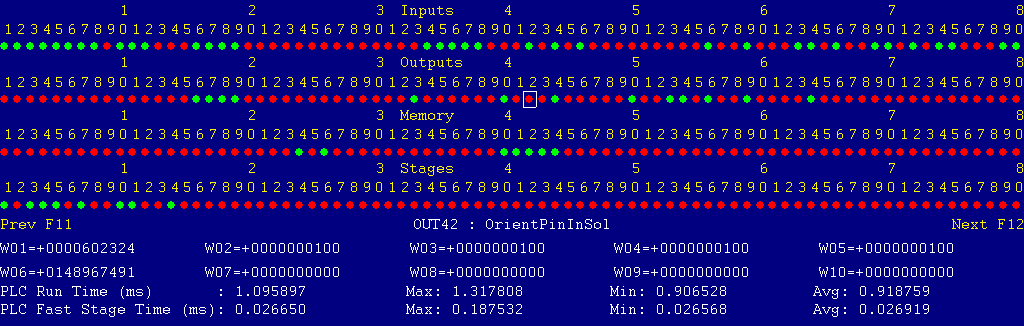

You can use the PLC Diagnostic display on the console to view Centroid PLC input, output and memory locations.

At the control's main screen, press Alt-I to activate the PLC Diagnostic display. Press Alt-I again to dismiss it.

Each page of the Diagnostic display shows four rows of red and green dots: the first row shows PLC inputs 1 through 80; the second row PLC outputs 1 through 80; the third row PLC memory bits 1 through 80; and the fourth row PLC program stages 1 through 80.

You can use the arrow keys to move a highlight box over any of these locations. The name of the highlighted location will be displayed in the center of the screen below the red and green dots.

For example, in the illustration above the highlight box is on Output #42: The dot below the 2, to the right of the superscript 4, on the second line.

Below the four rows of bit status information are ten numeric ("word") variable values, labeled W1 through W10. Some of these variables also hold useful status information, described with the error and fault conditions to follow.

There are multiple pages of Diagnostic data. With the Alt-I diagnostic display showing, you can use the F12 and F11 keys to scroll right and left. For example, pressing F12 once will shift to the page showing inputs and outputs 81 through 160, and word variables W11 through W20.

The PLC system can "invert" inputs in its software, making a closed input appear open and an open input appear closed. This is useful when the PLC logic assumes one type of sensor (e.g. normally-closed) and the machine is built with another type (e.g. normally-open). If the PLC system is inverting an input, then that input will be shown on the PLC Diagnostic display with an overscore above it. The color of the dot will represent the inverted state, not the actual electrical state. In other words, a green dot with an overscore represents an electrically open input, which appears to the PLC logic to be a closed input.

The PLC program can generate numerous system-specific fault, error and warning messages, in addition to the general control messages listed in the Centroid operator's manual.

You can use the PLC Diagnostic display, described above, to view the Centroid PLC input, output and memory locations mentioned with these fault and error conditions.

Messages with 9000-series message numbers are Faults. After resolving the problem, you must press and release the Emergency Stop button to clear a Fault.

Messages with 8000-series message numbers are Errors. Errors will cancel the program cycle and stop the spindle and coolant, but they do not then need to be explicitly reset.

Messages with 5000-series and 2000-series message numbers are Warnings and Informational Messages. They do not cancel the cycle and do not require any action to reset.

The control detected an internal error in processing the PLC logic program.

Report this error to your dealer, along with the values from W14 and W15. Also report what function the machine was performing when the fault occurred.

You must shut down and cycle the power to clear this fault.

References:

PLC W14: Copy of internal SV_PLC_FAULT_STATUS, indicating the type of problem PLC W15: Copy of internal SV_PLC_FAULT_ADDRESS, indicating the location of the problem

One of the servo amplifiers is reporting a fault condition.

If possible, check the LED display on the amplifier itself to see the specific fault code.

Press and release Emergency Stop to clear the fault.

References:

PLC MEM16: Axis #1 drive status. Green = okay, Red = fault PLC MEM17: Axis #2 drive status. Green = okay, Red = fault PLC MEM18: Axis #3 drive status. Green = okay, Red = fault PLC MEM19: Axis #4 drive status. Green = okay, Red = fault Schematic: Lines __

The control unit detected loss of communication from the operator panel in the Console.

Check for damage or disturbance to the cable between the console and the Oak control unit in the control cabinet.

Press and release Emergency Stop to clear the fault.

References:

Schematic: Lines __

The operator panel reported back to the control unit a loss of communication from the control unit. This indicates the return signal from the pendant is functioning normally, but the outgoing signal may have problems.

Check for damage or disturbance to the cable between the console and the Oak control unit in the control cabinet.

Press and release Emergency Stop to clear the fault.

References:

Schematic: Lines __

You exited the CNCM control software without first pressing Emergency Stop.

Always press Emergency Stop prior to exiting the control software.

Press and release Emergency Stop to clear the fault.

"9061 Mini PLC 1 Communication Fault"

The control lost communication with the PLC I/O expansion board.

Power down, open the cabinet, and check the connections at both ends of the gray cable which connects H8 on the Oak unit to H3 on the PLCADD1616 board.

Power up and check for a green "PLC OK" LED indication on the expansion board.

References:

PLC W36: bitmap of detected PLC expansion boards. 1 = one board detected Machine Parameter 900: bitmap of expected PLC expansion boards. 1 = one board expected Schematic: Lines __

The tool-clamped and the tool-unclamped switches were both closed at the same time.

This indicates faulty switches or damaged wiring.

References:

PLC INP__: Tool-clamped switch. Green = closed = fully clamped. Red = open = not fully clamped PLC INP__: Tool-unclamped switch. Green = closed = fully unclamped. Red = open = not fully unclamped Schematic: Lines __

The tool-pot-up and the tool-pot-down switches were both closed at the same time.

This indicates faulty switches or damaged wiring.

References:

PLC INP__: Pot-up switch. Green = closed = fully retracted up. Red = open = not fully retracted up PLC INP__: Pot-down switch. Green = closed = fully advanced down. Red = open = not fully advanced down Schematic: Lines __

You attempted to start an automatic program cycle, but Maintenance Mode (Aux12) is still active.

Press and hold the Aux12 key for one second to cancel Maintenance Mode.

"8181 ATC TOOL COUNTER NOISE (1)"

During ATC carousel rotation, the tool counter sensor opened sooner than expected when moving out of one tool position and into the in-transit state. This may indicate that the tool-counter input is affected by electrical noise, leading to false position counting.

This may also indicate that the rest position at the end of a previous carousel rotation was too close to the edge of the Geneva cam, perhaps due to a failing brake in the carousel rotation motor.

Use the Aux8 and/or Aux9 carousel index keys to rotate the carousel another position or two, so that it is again centered on one of the tool bins. Then press Alt-K to view the current carousel bin recorded in the software. If the recorded position does not match the actual position, rotate to position 1 and perform an M18 at the MDI prompt.

References:

PLC INP__: Tool counter sensor. Green = closed = in position. Red = open = between positions PLC W17: Current carousel position, as recorded by the PLC program Schematic: Lines __

During ATC carousel rotation, the tool counter sensor did not open, to indicate rotation from one tool position into the in-transit state, within the expected time. This may be because the sensor is faulty or out of position, so that it did not detect the movement. This may also be because the carousel failed to move, perhaps due to a failure to get power to the motor.

References:

PLC INP__: Tool counter sensor. Green = closed = in position. Red = open = between positions PLC OUT__: Carousel motor enable relay. Green = on = motor powered. Red = off PLC OUT__: Carousel motor direction relay. Green = rotate reverse. Red = rotate forward PLC W17: Current carousel position, as recorded by the PLC program Schematic: Lines __

During ATC carousel rotation, the tool counter sensor closed sooner than expected when moving from the in-transit state into the next tool position. This may indicate that the tool-counter input is affected by electrical noise, leading to false position counting.

Use the Aux8 and/or Aux9 carousel index keys to rotate the carousel another position or two, so that it is again centered on one of the tool bins. Then press Alt-K to view the current carousel bin recorded in the software. If the recorded position does not match the actual position, rotate to position 1 and perform an M18 at the MDI prompt.

References:

PLC INP__: Tool counter sensor. Green = closed = in position. Red = open = between positions PLC W17: Current carousel position, as recorded by the PLC program Schematic: Lines __

During ATC carousel rotation, the tool counter sensor did not close, to indicate rotation from the in-transit state to the next tool position, within the expected time. This may be because the sensor is faulty or out of position, so that it did not detect the movement. This may also be because the carousel stopped moving, perhaps due to a mechanical jam or to a failure to get power to the motor.

References:

PLC INP__: Tool counter sensor. Green = closed = in position. Red = open = between positions PLC OUT__: Carousel motor enable relay. Green = on = motor powered. Red = off PLC OUT__: Carousel motor direction relay. Green = rotate reverse. Red = rotate forward PLC W17: Current carousel position, as recorded by the PLC program Schematic: Lines __

The PLC program attempted to rotate the carousel, but the tool pot is still swung to the down position. Since PLC logic should preclude attempting to rotate the carousel while the pot is down, this error is more likely to be the result of a faulty pot-down or pot-up sensor.

An 8186 error indicates the problem was detected while starting the rotation out of one tool position, towards the in-transit state.

This error will be reported if the pot is fully down (pot-down input is closed), and also if the pot is not fully up (pot-up input is open).

If the pot really was out of position, use the Maintenance Mode controls to raise it.

It the pot was not really down, use the PLC Diagnostic display or the PLC Detective tool to monitor the pot-up and pot-down sensor inputs while you cycle the pot through its motions. Verify that the pot is moving its full stroke, and staying in position after it arrives. Adjust or replace the sensors if they are giving incorrect signals.

References:

PLC INP__: Tool pot up sensor. Green = closed = pot up. Red = open = pot not fully up PLC INP__: Tool pot down sensor. Green = closed = pot down. Red = open = pot not fully down PLC OUT__: Tool pot up solenoid. Green = on = swing pot up. Red = off PLC OUT__: Tool pot down solenoid. Green = on = swing pot down. Red = off Schematic: Lines __

The PLC program attempted to rotate the carousel, but the tool pot is still swung to the down position. Since PLC logic should preclude attempting to rotate the carousel while the pot is down, this error is more likely to be the result of a faulty pot-down or pot-up sensor.

An 8187 error indicates the problem was detected while continuing the rotation from the in-transit state to the next tool position.

This error will be reported if the pot is fully down (pot-down input is closed), and also if the pot is not fully up (pot-up input is open).

If the pot really was out of position, use the Maintenance Mode controls to raise it.

It the pot was not really down, use the PLC Diagnostic display or the PLC Detective tool to monitor the pot-up and pot-down sensor inputs while you cycle the pot through its motions. Verify that the pot is moving its full stroke, and staying in position after it arrives. Adjust or replace the sensors if they are giving incorrect signals.

References:

PLC INP__: Tool pot up sensor. Green = closed = pot up. Red = open = pot not fully up PLC INP__: Tool pot down sensor. Green = closed = pot down. Red = open = pot not fully down PLC OUT__: Tool pot up solenoid. Green = on = swing pot up. Red = off PLC OUT__: Tool pot down solenoid. Green = on = swing pot down. Red = off Schematic: Lines __

The PLC received a tool-change or tool prestage request for an invalid carousel position: a position that is not between 1 and the number of positions specified in Machine Parameter 161.

References:

Machine Parameter 161: number of positions in the tool carousel PLC W10: Carousel position that was requested by the CNC PLC W19: PLC copy of Parameter 161, number of positions in the tool carousel

An automatic tool change was requested, but there is not sufficient air pressure to operate the pneumatic ATC components.

Verify that air is connected and turned on, and that pressure is within the range specified by the machine builder.

If this error occurs in the middle of a tool change, you may need to increase the size of the supply line, or install an accumulator tank, in order to maintain pressure at the machine during tool changes.

References:

PLC INP__: Air pressure switch. Green = closed = good pressure. Red = open = low or no pressure Schematic: Lines __

During an automatic tool change, or after an M19 spindle orientation for any other purpose, the spindle failed to maintain its orient position.

This is usually due to some sort of external disturbance, such as excessive force on the tool or tool holder.

References:

PLC MEM34: Orient complete flag. Green = 1 = in orient. Red = 0 = out of orient Schematic: Lines __

The control received, or thought it received, a command to rotate the spindle (either to run, to orient, or to shift gears if applicable) while the tool drawbar was in the unclamped position.

References:

PLC MEM21: Spindle-run flag. Green = 1 = spindle should be running in normal operation PLC MEM24: Run-for-orient flag. Green = 1 = spindle should be running in order to orient PLC INP__: Tool-clamped switch. Green = closed = fully clamped. Red = open = not fully clamped PLC INP__: Tool-unclamped switch. Green = closed = fully unclamped. Red = open = not fully unclamped Schematic: Lines __

During an automatic tool change, or after an M19 orientation request for

any other purpose, the spindle failed to come to a stop so that

orientation could proceed.

"8211 ATC NOT READY: MZ_ACK"

During an automatic program cycle, with no tool change in progress, the signal from the CNC to the PLC which reports that initial head positioning for a tool change is complete was set (1). This flag should only be set for short intervals during a tool change.

Report this condition to your dealer.

"8212 ATC NOT READY: TOOL CLAMP INP"

During an automatic program cycle, with no tool change in progress, the tool-clamped switch was open.

This indicates either a malfunctioning or out-of-position switch, or an uncommanded tool release.

References:

PLC INP__: Tool-clamped switch. Green = closed = fully clamped. Red = open = not fully clamped Schematic: Lines __

During an automatic program cycle, with no tool change in progress, the tool-unclamped switch was closed.

This indicates either a malfunctioning or out-of-position switch, or an uncommanded tool release.

References:

PLC INP__: Tool-unclamped switch. Green = closed = fully unclamped. Red = open = not fully unclamped Schematic: Lines __

During an automatic program cycle, with no tool change in progress, the tool-counter input was open.

This usually indicates that the tool carousel is out of position, perhaps due to an error or interruption in a preceding tool change.

It could also indicates a malfunctioning or out-of-position sensor, or uncommanded carousel movement.

References:

PLC INP__: Tool counter sensor. Green = closed = in position. Red = open = between positions Schematic: Lines __

During an automatic program cycle, with no tool change in progress, the arm-home sensor was not open, suggesting that the changer arm is not in its parked position.

Note that the arm sensors are typically inverted in the PLC software. They are usually proximity sensors which line up with notches in rotating cams, so the sensor is open (not tripped) when it is in position. With PLC input inversion, these sensors are made to appear closed (green) when the cam is in the desired position.

References:

PLC INP__: Arm-at-home sensor. Green = closed = at home. Red = open = not at home Schematic: Lines __

During an automatic program cycle, with no tool change in progress, the arm-clamp sensor was open, suggesting that the changer arm is rotated to the tool-gripping position.

Note that the arm sensors are typically inverted in the PLC software. They are usually proximity sensors which line up with notches in rotating cams, so the sensor is open (not tripped) when it is in position. With PLC input inversion, these sensors are made to appear closed (green) when the cam is in the desired position.

References:

PLC INP__: Arm-at-clamp sensor. Green = closed = at clamp position. Red = open = not at clamp position Schematic: Lines __

During an automatic program cycle, with no tool change in progress, the arm-stop sensor was not open, suggesting that the changer arm is neither in its parked position nor in the tool-gripping position.

Note that the arm sensors are typically inverted in the PLC software. They are usually proximity sensors which line up with notches in rotating cams, so the sensor is open (not tripped) when it is in position. With PLC input inversion, these sensors are made to appear closed (green) when the cam is in the desired position.

References:

PLC INP__: Arm-at-stop sensor. Green = closed = at a stop. Red = open = not at a stop Schematic: Lines __

During an automatic program cycle, with no tool change in progress, the tool-pot-down switch was closed, indicating that the pot is advanced down.

This is usually due to an out-of-position switch. It could also be due to the pot having been left in the down position after a failed tool change.

If the pot is down, use the Maintenance Mode controls to retract it.

References:

PLC INP__: Pot-down switch. Green = closed = fully advanced down. Red = open = not fully advanced down Schematic: Lines __

During an automatic program cycle, with no tool change in progress, the tool-pot-up switch was open, indicating that the tool pot is not fully retracted up.

This is usually due to an out-of-position switch. It could also be due to the pot drifting or getting pushed out of its retracted position.

References:

PLC INP__: Pot-up switch. Green = closed = fully retracted up. Red = open = not fully retracted up Schematic: Lines __

During an automatic tool change, the PLC requested that the CNC move the head into its initial position (tool-changing height), but the CNC did not report the move complete within the allowed time.

This can occur if Z axis movement is slowed or paused during the

tool change. Avoid pressing Feed Hold while a change is in progress.

"8242 ATC NEW TOOL ROTATION TIMEOUT"

During an automatic tool change, carousel rotation to the requested

tool did not complete within the allowed time.

"8243 ATC ORIENT TIMEOUT"

During an automatic tool change, the spindle did not reach and hold its orient position within the allowed time.

References:

PLC MEM34: Orient complete flag. Green = 1 = in orient. Red = 0 = out of orient Schematic: Lines __

During an automatic tool change, the drawbar failed to open and release the old tool within the allowed time.

References:

PLC OUT__: Tool-unclamp solenoid. On = open drawbar, unclamp tool PLC INP__: Tool-unclamped switch. Green = closed = fully unclamped. Red = open = not fully unclamped Schematic: Lines __

During an automatic tool change, the drawbar failed to close and grip the new tool within the allowed time.

References:

PLC OUT__: Tool-unclamp solenoid. On = open drawbar, unclamp tool PLC INP__: Tool-clamped switch. Green = closed = fully clamped. Red = open = not fully clamped Schematic: Lines __

During an automatic tool change, the CNC did not acknowledge the completion

signal from the PLC within the allowed time.

"8271 ATC POT DOWN TIMEOUT"

During an automatic tool change, while waiting for the tool pot with the new tool to swing down into the ready position, the pot-down switch failed to close within the allowed time.

This could be due to a mechanical obstruction or jam; to a lack of air pressure; or to a failed solenoid valve.

References:

PLC INP__: Pot-down switch. Green = closed = fully advanced down. Red = open = not fully advanced down Schematic: Lines __

During an automatic tool change, while waiting for the tool pot with the new tool to swing down into the ready position, spindle orientation was lost. The tool change cannot proceed with the spindle out of orient.

References:

PLC INP__: Orient-complete signal from spindle drive. Green = closed = in orient. Red = open = not in orient PLC MEM34: PLC internal orient-complete flag. Green = on = in orient. Red = off = not in orient Schematic: Lines __

During an automatic tool change, the changer arm failed to move out of

its parked position within the allowed time.

"8274 ATC ARM CLAMP WAIT STOP TIMEOUT"

During an automatic tool change, the changer arm left its parked position,

but failed to move into the tool-gripping position within the allowed time.

"8275 ATC AHTC HOME/CLAMP NO STOP"

During an automatic tool change, the arm-clamp sensor indicated that the changer arm had moved into the tool-gripping position, but the arm-stop sensor failed to indicate arrival at a stopping place.

This is probably due to either to misalignment of the sensors or cams,

or to a wiring or sensor failure.

"8276 ATC ARM DOWN 180 UP TIMEOUT"

During an automatic tool change, the changer arm failed to move down out of

the tool-gripping position within the allowed time.

"8277 ATC ARM D180U CLAMP ERROR"

During an automatic tool change, as the arm was beginning the move down,

the tool drawbar clamp failed to stay open.

"8278 ATC ARM D180U WAIT STOP TIMEOUT"

During an automatic tool change, the changer arm moved down from the

tool-gripping position, but failed to complete the move down, 180°

rotation, and move up within the allowed time.

"8279 ATC ARM D1UWS CLAMP ERROR"

During an automatic tool change, as the arm was making the move down, 180°

rotation, and move up sequence, the tool drawbar clamp failed to stay open.

"8280 ATC ARM D180U HOME/CLAMP NO STOP"

During an automatic tool change, the arm-clamp sensor indicated that the changer arm had completed the down - 180° - up movement back into the tool-gripping position, but the arm-stop sensor failed to indicate arrival at a stopping place.

This is probably due to either to misalignment of the sensors or cams,

or to a wiring or sensor failure.

"8281 ATC ARM TO HOME TIMEOUT"

"8282 ATC ARM HOME WAIT STOP TIMEOUT"

"8283 ATC ARM HOME/CLAMP NO STOP"

At the end of an automatic tool change, while waiting for the tool pot with the old tool to swing up into the carousel, the pot-up switch failed to close within the allowed time.

This could be due to a mechanical obstruction or jam; to a lack of air pressure; or to a failed solenoid valve.

References:

PLC INP__: Pot-up switch. Green = closed = fully retracted up. Red = open = not fully retracted up Schematic: Lines __

The PLC program requested display of a message on the screen, but the provided message code was not valid.

This indicates an error in the PLC program. Report the message to your dealer, along with the value in PLC variable W16.

References:

PLC W16: stores the invalid message code

The PLC hardware detected the presence of an I/O expansion board, but the setting of Machine Parameter 900 did not tell it to expect that board in the system.

On the basic ATC systems supported here, there should be one I/O expansion board installed, and Machine Parameter 900 should be set to 1.0.

References:

PLC W36: bitmap of detected PLC expansion boards. 1 = one board detected Machine Parameter 900: bitmap of expected PLC expansion boards. 1 = one board expected

The program attemped to run an M3 spindle-start code, but the control is still in Manual Spindle mode.

Press the SPIN AUTO/MAN key in the top row of the operator panel

to select Auto mode (LED on); then press CYCLE START to

resume program operation.

"2021 Axis Faults Cleared"

A previous servo drive fault condition has been resolved,

and cleared with Emergency Stop.

"2024 PLC Faults Cleared"

A previous PLC fault condition has been resolved,

and cleared with Emergency Stop.

"2035 KEYBOARD JOGGING DISABLED"

You inadvertently pressed a keyboard combination that is

used for keyboard jogging controls, but keyboard jogging

features have been disabled on this machine.

"2099 Message Cleared"

A previous fault condition has been cleared with Emergency Stop.

"2185 TOOL NOISE FAULT CLEARED"

This message should appear after an 8181 or 8183 error (see above), when

you jog the carousel back into a known position.

"2201 --- ATC INITIALIZED ---"

This message is displayed after an M18 or ATC Init operation, to show that the PLC has updated its carousel-position and tool-number values.

26-May-2025

http://www.cncsnw.com/UnifiedATCSwingArmOperatorInst.htm